Frugal engineering became a fashionable term thanks largely to Carlos Ghosn, the former CEO of Renault-Nissan. However, it was the late Osamu Suzuki who truly was the father of frugality which he practised with relentless passion for decades at Suzuki Motor Corporation.

The kind of costing efficiencies generated as a result helped this small carmaker hold its own in a market like Japan against big brands like Toyota, Honda and Nissan while racing away to market leadership in India.

The way Maruti has redefined the game in terms of costing efficiencies and creating a niche in the compact car space is a result of O Suzuki’s incredible manufacturing acumen, a trait that even his fiercest rivals have acknowledged.

It is this passion and commitment to achieving an astonishing cost structure that has primarily helped Maruti stay comfortably ahead of competition. More importantly, it was O Suzuki’s unrelenting focus on keeping wasteful expenditure in check that did the trick in keeping his company remain profitable.

Small is beautiful

“He believed in the basic principle of small is beautiful which was the calling card for Maruti. Beyond this, Osamu Suzuki was the one who created a template for partnerships between Indian and Japanese component makers,” a top executive told ETAuto.

According to him, he would constantly check every conceivable area where costs could be cut and this lesson was drilled into the supplier community too. Suzuki would also urge them not to get into needless business diversifications and was of the view that it was imperative to focus on the core business.

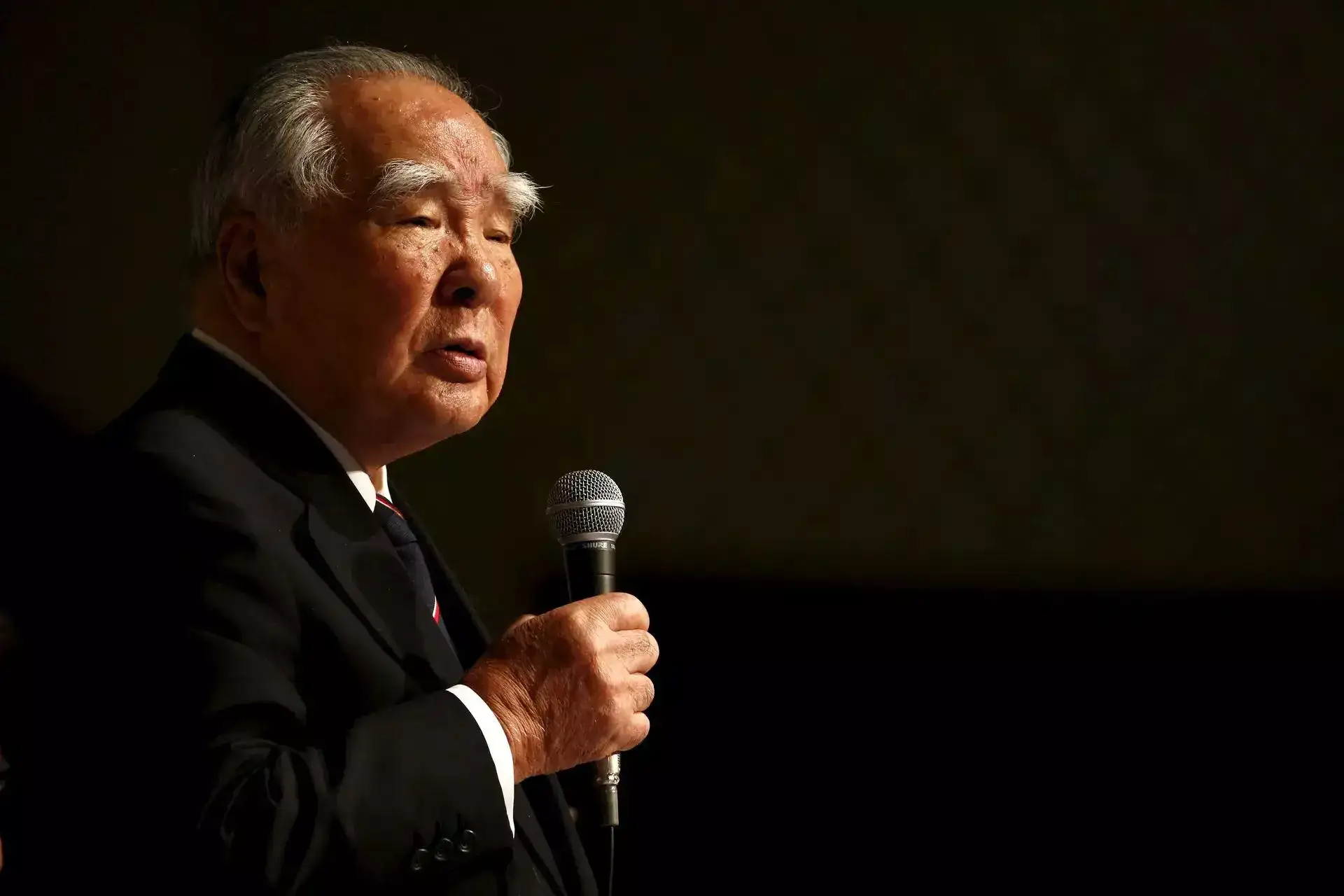

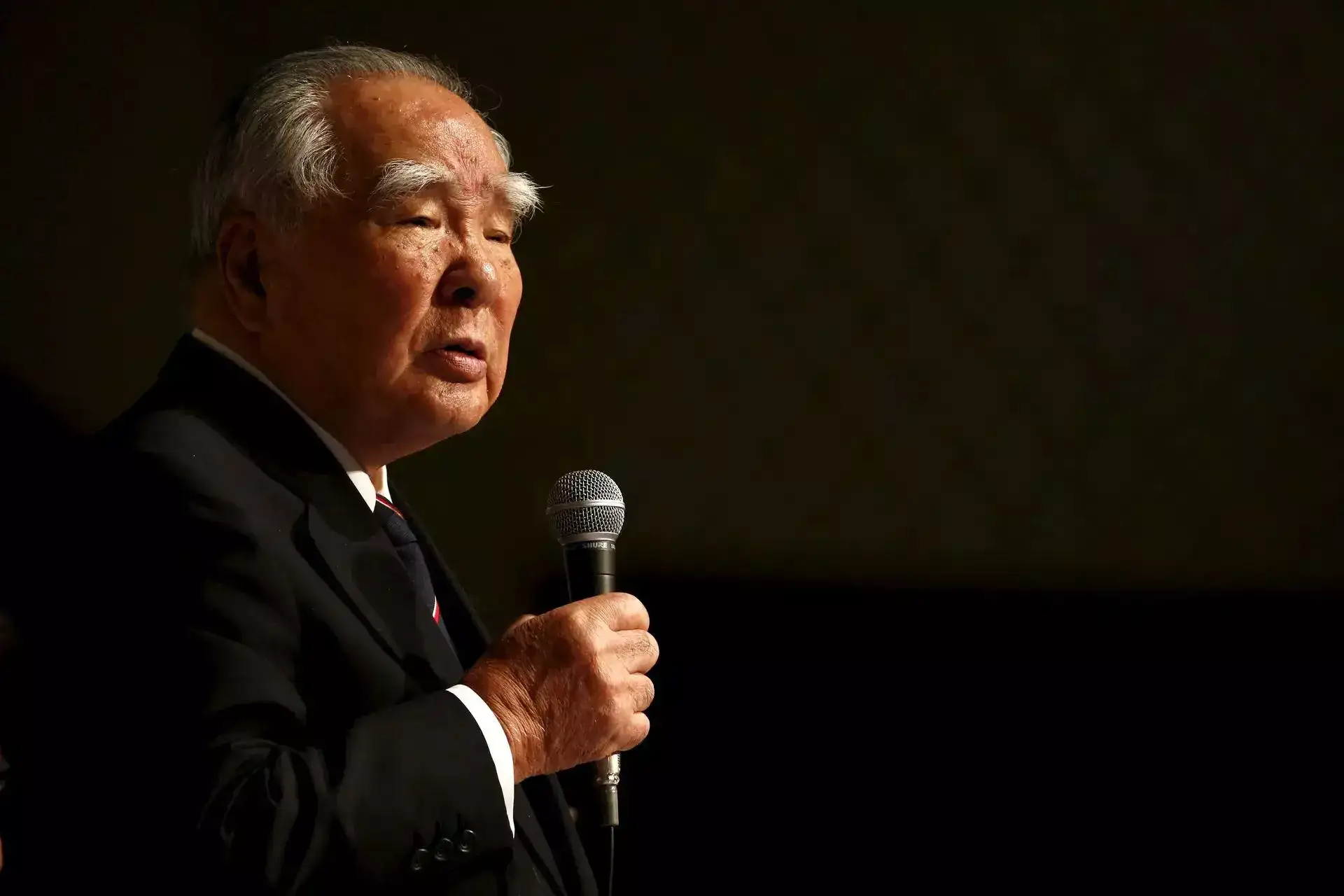

As the executive put it, “His view was that as manufacturers, we should be smelling petrol and not perfume. The underlying message was to become the best in whatever we were doing and not get distracted.” Suzuki reiterated this belief once again at an ACMA (Automotive Component Manufacturers Association of India) convention in New Delhi nearly a decade ago.

“I request all suppliers to reinvest your profits in the same business and not in hotels or leisure,” he said to loud applause from the audience. At this event, he spoke in Japanese with the help of an English interpreter but this was of little consequence to the crowd which listened spellbound.

The Maruti journey

O Suzuki recalled the time when the then Maruti Udyog started operations in 1983 and it was clear that localisation was imperative for an effective cost structure. The Japanese automaker then began investing in joint ventures with its Indian suppliers and there are nearly 20 of them today which are a critical part of the company’s global supply chain.

By spearheading the creation of a robust ancillary supplier base in India, Maruti has now become a global small car hub and is also the country’s largest exporter. Now, in its stronger alliance with Toyota Motor Corporation, this responsibility will only magnify in the future with new forays in technology, especially electrification.

The Suzuki chief also made it clear during the ACMA session that quality was an imperative to make the India story in automobiles a reality. While the Make in India slogan was fine, it made sense to look at it in a larger context with the tagline being a more expansive ‘Quality in India to Make in India’.

Once this was in place, suppliers could even pull off the impossible and enable India to overtake China and the US in the global automobile space. For now, this is still a pipe dream but as he clearly indicated, the sky was the limit.

Quality is the key

The spate of vehicle recalls during this period also reminded O Suzuki that quality was the key to success which meant that vendor selection became even more critical for automakers across the world.

To those who worked closely with him, he could have have come across as a micromanager who left nothing to chance but this was perhaps understandable given the passion he had for his job and company. It was obvious that he did not suffer fools and had little time for anything else except business where all the hard work has paid off.

“Look at it this way. Japan’s auto industry is witnessing new marriages like Honda and Nissan as a means of survival. And then you have a small carmaker like Suzuki which continues to do well and has been the market leader of the world’s third largest car producer for over three decades,” says an industry official. It was a classic case of a David emerging triumphant in a landscape dominated by Goliaths.

Sure, Suzuki Motor Corp also has had its share of alliances like General Motors which lasted many years till the American automaker decided to focus more on Daewoo which it had acquired two decades earlier.

Moving beyond VW

It then moved to a new partnership with Volkswagen which promised the moon but ended up being a nightmare for both partners. O Suzuki was exasperated with the way things were going and was relieved when the divorce finally came through and he uttered those famous words: “It used to feel like a small bone was stuck in the back of my throat. It is so refreshing now.”

Yet, the Suzuki Chairman was absolutely aware of the fact that his company needed the scale and technology to keep itself relevant in the future. The alliance with Toyota was the best thing that could have happened and, over the years, the two companies have expanded its scope. What began with product swaps has now reached the next level of joint development in electric.

Toyota clearly needs Suzuki’s support in regions like India where its own presence was marginal with barely one success story in the form of the Innova. Today, the Toyota-Suzuki partnership in India has grown by leaps and bounds with new plants due to be commissioned during the course of this decade.

Suzuki legacy stays intact

“Teaming up with Toyota reflected the sagacity of Osamu Suzuki. He knew that the company he had nurtured so carefully for decades would be in good hands now. Even with his passing, the Suzuki Motor Corp legacy will be intact with Toyota taking it to the next level of growth,” said the observer quoted earlier.

Osamu Suzuki was truly a doyen of manufacturing who created new benchmarks in costing across the automobile industry. No other small carmaker, including Toyota’s own Daihatsu entity, could cope with this kind of structure. The nonagenarian will be forever remembered for his razor sharp focus on frugality which will be almost impossible to emulate in the years to come.